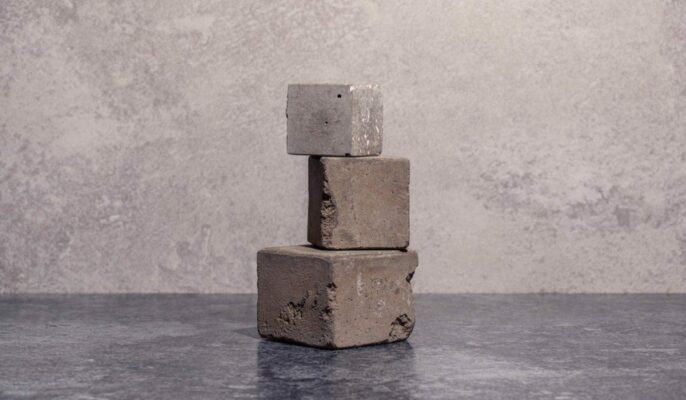

Geopolymer is a type of construction material that does not use traditional Portland cement. Instead, it relies on materials rich in silica (SiO₂) and alumina (Al₂O₃) as its main components. Common sources of these elements include fly ash, metakaolin, and slag. These materials undergo a chemical reaction with alkaline activators to form geopolymer binders.

There are two main types of alkaline activators used in this process: sodium hydroxide (NaOH) and sodium silicate solution (Na₂O·nSiO₂). These are widely available and cost-effective compared to other alkaline chemicals. The activators initiate a process called geopolymerization, which transforms the raw materials into a strong, durable binder.

The performance of the geopolymer depends on the ratio of the materials used. A commonly used sodium silicate solution has a SiO₂/Na₂O molar ratio between 1.50 and 2.50. A higher ratio increases the silica content in the system, affecting the viscosity and gel formation of the geopolymer. Additionally, materials such as sand, fibers, or special additives can be included to enhance specific properties.

Key Properties of Geopolymers:

-

Fire resistance

-

Chemical resistance

-

Low carbon emissions

-

High strength

-

Environmentally friendly

These advantages have led to growing interest in geopolymers across various industries, including:

-

Construction – Used in concrete, bricks, and chemical-resistant surfaces

-

Chemical industry – Suitable for factory floors, chemical tanks, and leak-proof barriers

-

Fireproofing – Acts as insulation in buildings and vehicles; also used in fire-resistant bricks

-

Structural repair – Ideal for repairing floors, bridges, and pipelines

-

Aerospace – Lightweight and fire-resistant materials for aircraft or spacecraft

-

Specialized structures – Suitable for underground or marine applications

Geopolymer is considered a high-potential material for the future due to its environmental benefits, sustainability, and ability to meet specialized industrial demands.

References:

- Meskhi, B., Beskopylny, A. N., Stel’makh, S. A., Shcherban, E. M., Mailyan, L. R., Shilov, A. A., El’shaeva, D., Shilova, K., Karalar, M., Aksoylu, C., & Özkılıç, Y. O. (2023). Analytical review of geopolymer concrete: Retrospective and current issues. Materials, 16(3792).

- Rattanasik, U. (2017). Geopolymer materials [วัสดุจีโอพอลิเมอร์]. Bangkok: Thailand Concrete Association.